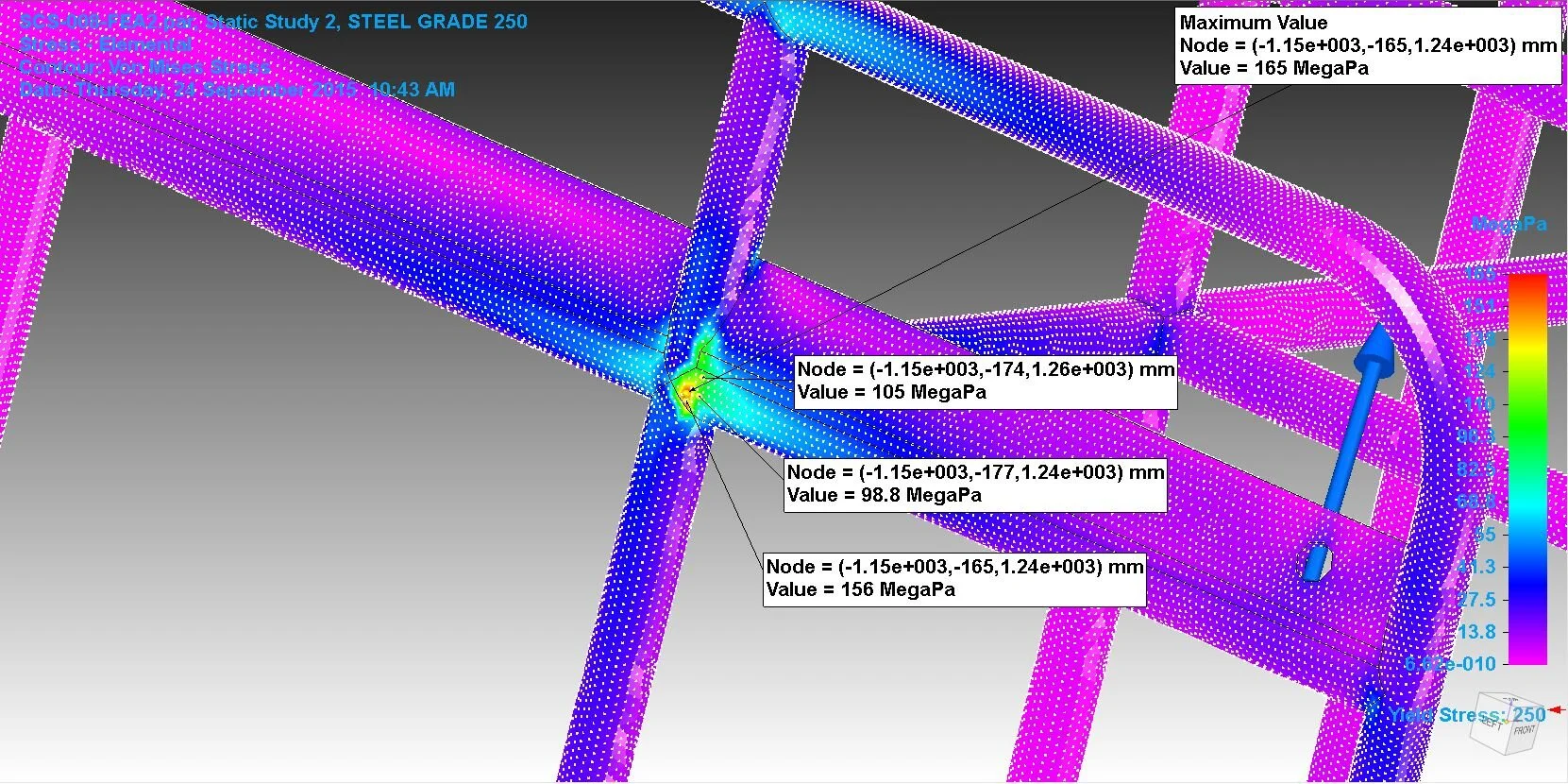

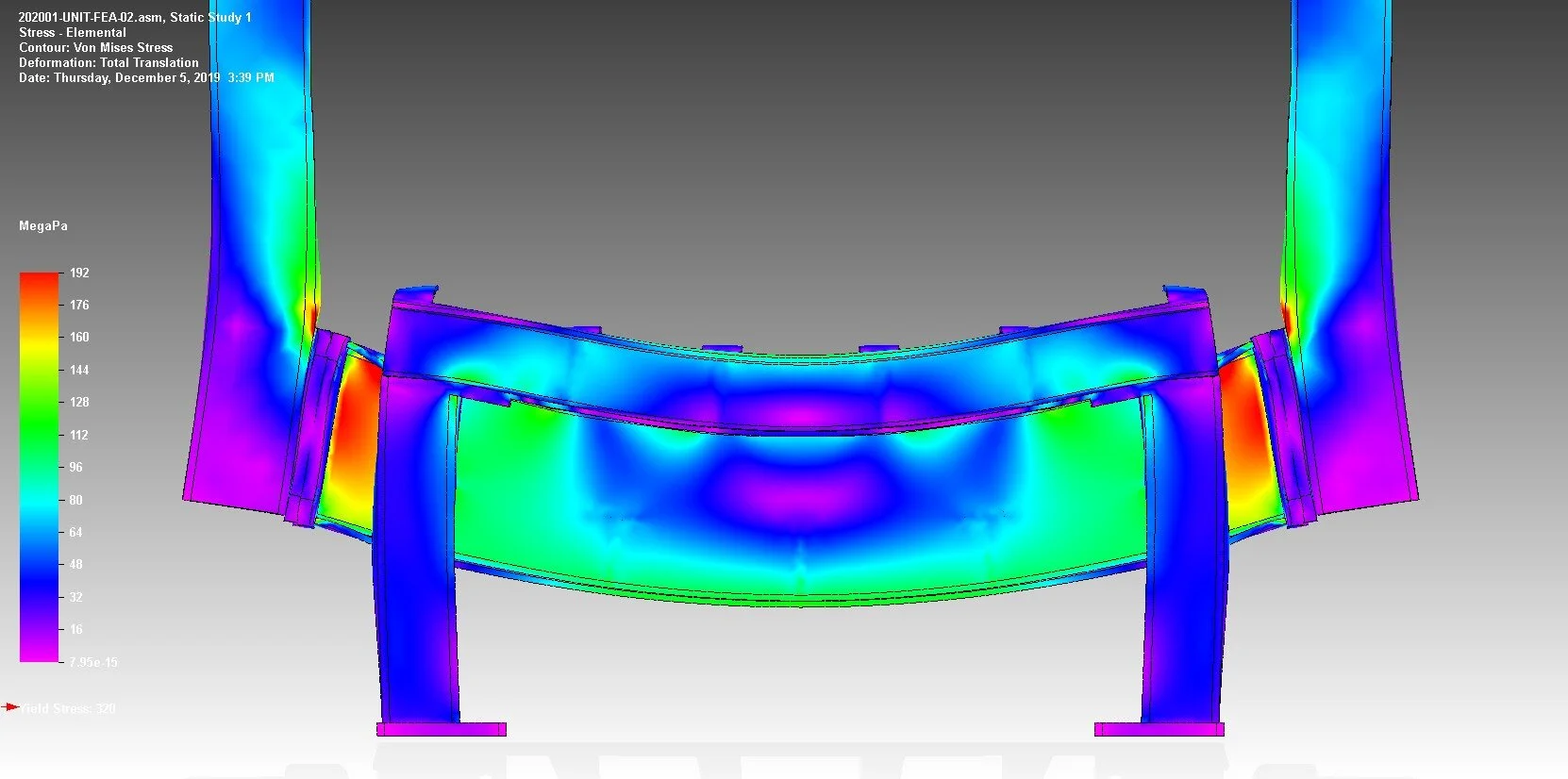

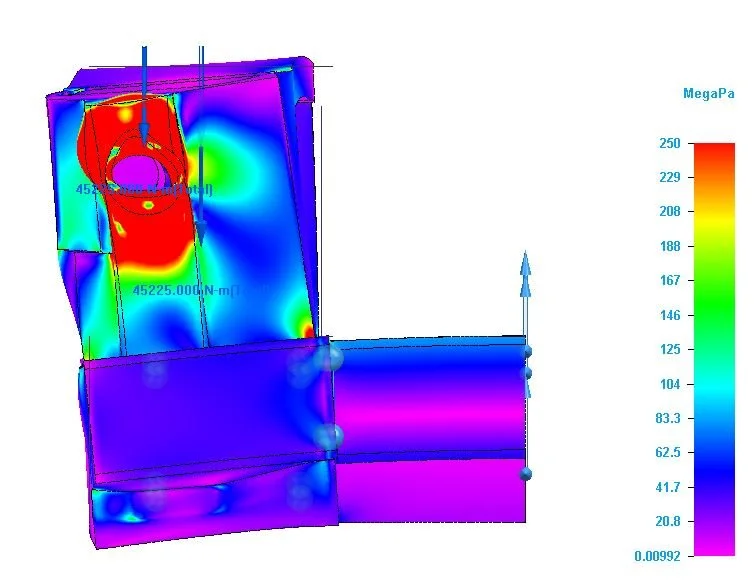

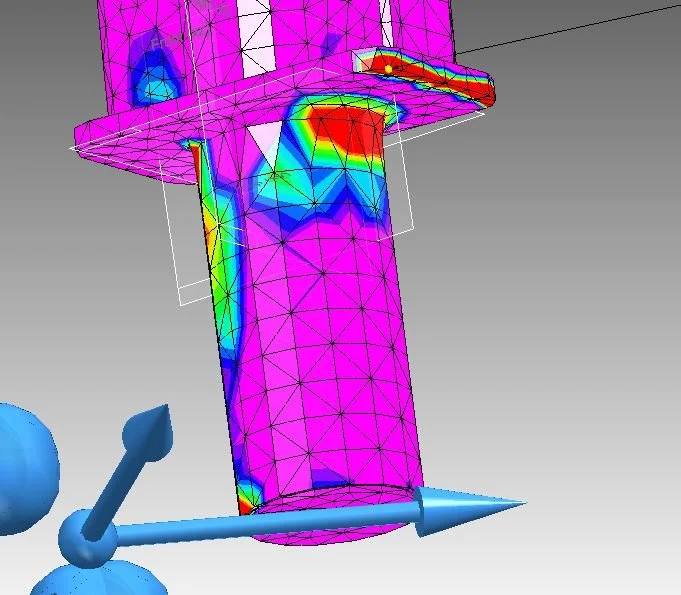

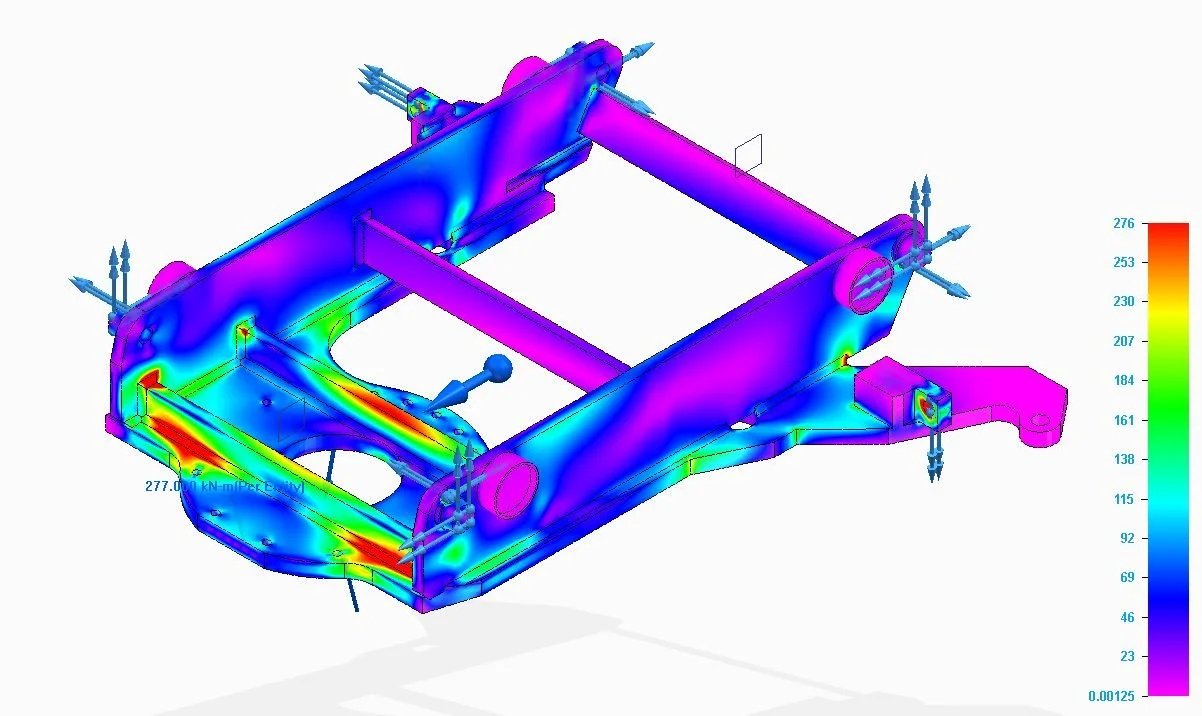

Finite Element Analysis (FEA)

Our Finite Element Analysis (FEA) services assess Stress, Strain, Fatigue, Deflection, for plant and equipment in mines, farms, and municipal works. rang Imagineering offers specialist Finite Element Analysis (FEA) services to assess stress, strain, fatigue, and deflection in plant equipment, mobile plant, and operational infrastructure.

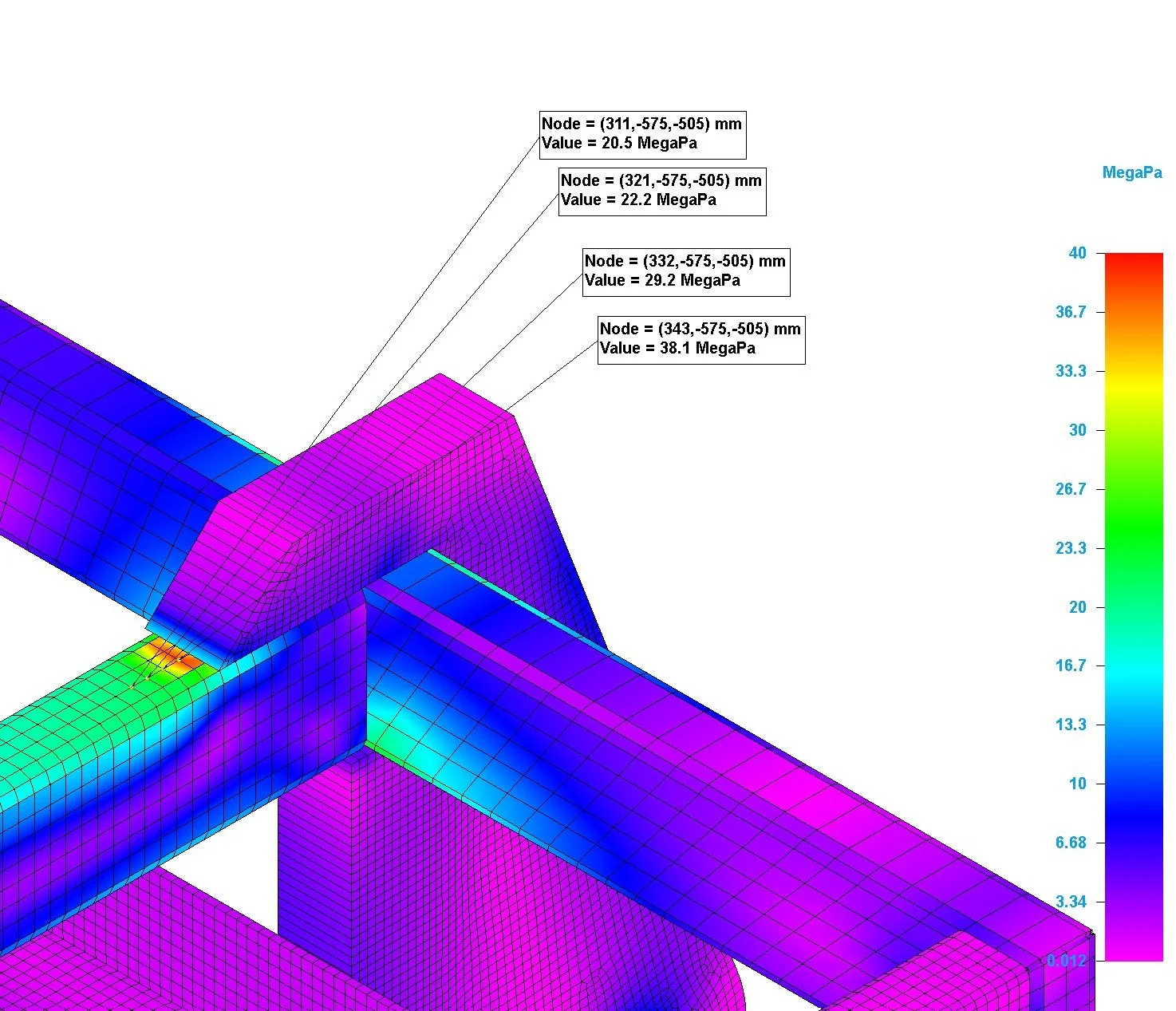

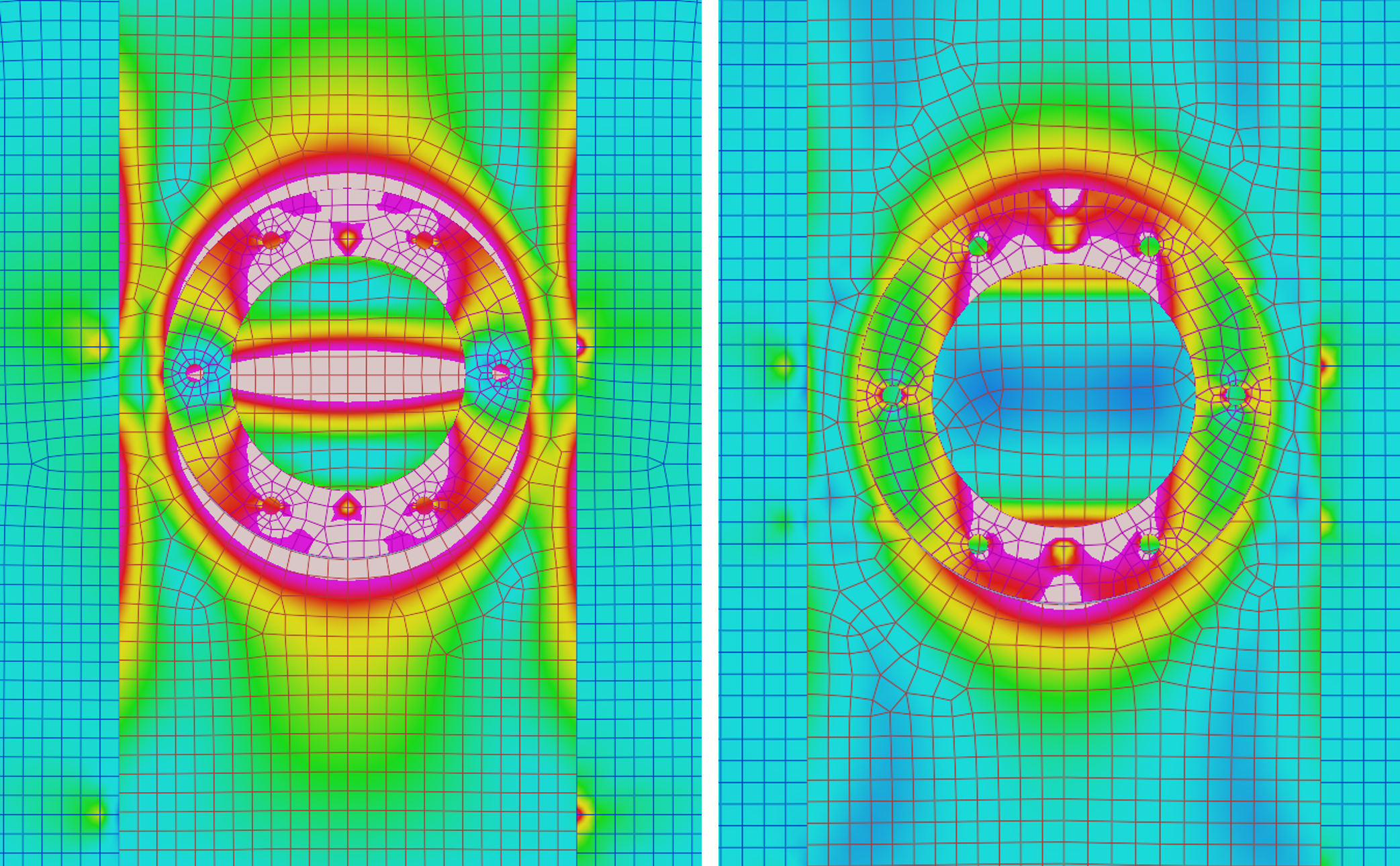

FEA is also used to verify the structural performance of welded frames, support brackets, equipment skids, and other components subject to mechanical loading.

Our engineers use advanced simulation software to help clients identify risks, optimise designs, and meet compliance standards.

Service Inclusions:

Structural stress and deflection analysis

Fatigue life assessment and crack growth prediction to BS7608

Modal and Vibration analysis

Pressure vessel and tank integrity modelling

Lifting equipment and load handling assessment

Dynamic and thermal analysis for operational plant

Why Choose Trang for FEA?

We specialise in practical, operationally focused analysis — not just theoretical models. Our FEA outputs are designed to be understandable by site personnel and integrate into maintenance and upgrade strategies.

We regularly perform simulation work on components that form part of broader structural assemblies, including platforms, tanks, access frames, and structural supports.

Common standards we use:

AS3990 - Mechanical Equipment - Steelwork

AS4100 - Steel Structures

AS1657 - Fixed platforms, walkways, stairways and ladders - Design, construction and installation

API650 - Welded Tanks for Oil Storage

API653 - Tank Inspection, Repair, Alteration, and Reconstruction

BS 7608 - Guide to fatigue design and assessment of steel products

NHVR Load Restraint

Piping Design to AS4041 & ASME B31.3